Jeffrey Gueble

Automation - Robotics - Mechatronics

Consulting & Custom Automation Development

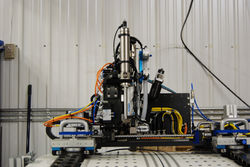

SealFast Robot

SealFastFront view of SealFast Robot |  Rivet ShooterBased on an automatic screwdriver head, the rivet head accepts rivets shot from the feed cart at high rate. |

|---|---|

TurretEarly version using rotary turret concept to change tools. |  IsometricIsometric view of SealFast Robot |

DSC_0047 |  Quick-Change LockQuick-change locking feature. |

Side ViewSide view of SealFast Robot |  FeederOne of the blow-feeders for the rivets. |

Robot |

The SealFast robot is a prototype built for Boeing. The robot is intended for use in joining fuselage pieces together, after the hole pattern is drilled.

The concept involves eight fastener feeders, which can blow feed different sizes of the rivets to the insertion head. The robot moves along on two rails, using vision to precisely locate each hole.

At a particular hole, the robot locates the hole with a skewed camera, and positions the dispense head over the hole. Adhesive is dispensed into the hole, and the correct rivet size, as determined by the program, is fed to the insertion head. The rivet is then pushed into the hole, and an operator applies the clinch fastener to the end of the rivet. As the fastener is clinched onto the rivet, the robot senses the shock load on the insertion head, and releases the rivet, moving to the next hole.