Jeffrey Gueble

Automation - Robotics - Mechatronics

Consulting & Custom Automation Development

OPBH Auto

DialTop view of the rotary indexer. |  Robot HordeSide view of the work cell showing the four robots. |

|---|---|

Seal FeederRecirculating seal feeder showing the seals being carried into the pick zone. |  Resonator Load InfeedTrays stacked up as they enter the resonator loading station. |

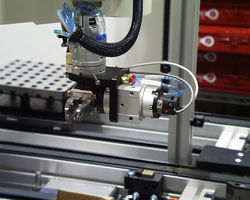

Resonator LoadGripper and the walking beam of the resonator loading station. |  LabOPBH Auto in the laboratory before installation on the factory floor. |

Brush InstallBrush install station showing the assembly after the brush tip is installed. |  Body LoadView of the body loading station and tube feeder. |

Resonator GripperView of the resonator gripper in the load position. |  Body FeederShot of the body on a gripper as the robot exits the feeder area. |

OPBH Auto assembles brush heads at a rate of 1200 units per hour. It is a unique cell, in that it uses four SCARA robots arranged around an servo indexer. The robots are mildly synchronized to ensure that they can work within overalpping work envelopes and not crash.

The process starts with the body load station, where the supremely irregular body plastic is inserted into an assembly nest. The part is rotated to the next station, where the seal is installed.

The seal, a two-part component, with an elastomeric shell is a particularly difficult part to handle. The part is designed such that it can stick together when held in bulk, and the elastomeric shell is very sticky. A vision-assisted recirculating feeding system was used to solves this problem. The seals are picked with vision from a conveyor belt, which dumps the unselected components back into a bin where they are recirculated into the pick zone.

The seal was also difficult to install because the center through-hole is rectangular, and must be properly oriented before installation. The solution was to use a second camera to locate and orient the hole, and then rotate the seal during installion.

Seal installation is followed by insertion of the resonant motor, which was performed using a servo press atop a walking beam. The walking beam was loaded at the infeed side with a robot from trays.

The final step in the assembly was the brush tip installation, which required a special station to displace the body plastic tip to allow for the brush to be press fit onto the motor shaft.